How we got involved using 3D Seismic Data

Here is what set us apart as an independent many years ago…

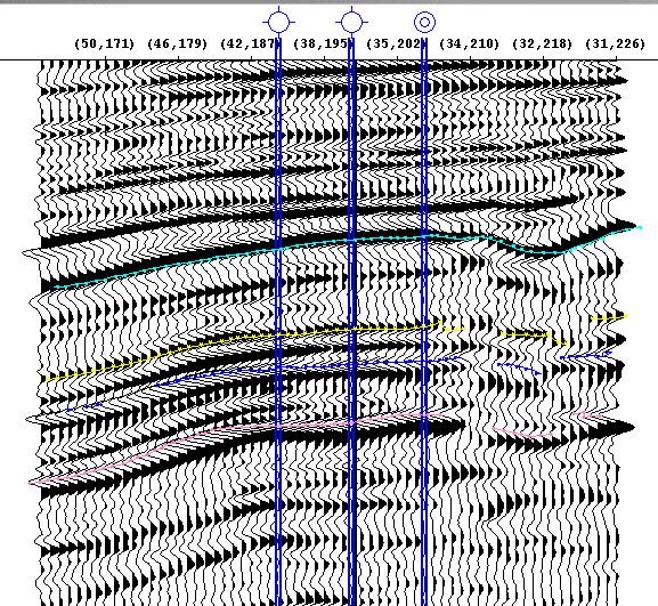

Over the years the oil industry improved the tools used in reflection seismic recording and as computer power increased, allowing manipulation of massive amounts of data, the method of recording 3Dimensional seismic surveying became more practical. 3D seismic data collects information from a large cube of data; miles on every side and miles deep into the earth. The data points in this cube are only feet apart in the subsurface, allowing geophysicists to map small structures and faults with precision.

2D Seismic Rendering from a 3D Cube of Data

A Stroke of “Luck”

Now step back to 1971. A previous partner of Ranken Energy Corporation using traditional two-dimensional seismic data identified a possible Basal Oil Creek Sand structural prospect to be drilled in southern Oklahoma. They named the well the Lema #1-21 and drilled a well that had oil shows in the Basal Oil Creek Sandstone but the well was deemed non-commercial and it was plugged.

Some years later this same company shot a proprietary 3D survey in the area of the Lema #1-21 well. We acquired that 3D survey and in 2004 Ranken proposed a well only 700 feet to the east of the Lema well and made a discovery well that produced over 150,000 barrels of oil prior to Ranken selling the well. This location was picked utilizing the 3D seismic data previously referred to.

The quality of the seismic data being used is excellent and though we are twenty years past the time when it was originally recorded, we were able to precisely identify the structure and drill the well with confidence.

The Impact of Technology

This success launched Ranken Energy on an aggressive program of drilling utilizing proprietary 3D seismic data. Ranken Energy has drilled over 185 wells in south central Oklahoma using this data and we subsequently distributed over $274 million net of severance taxes to our partners since 2001.

US$274,000,000+

- Wells Drilled Since 1986 = 350+

- Wells Drilled since implenting 3D seismic data in 2001 = 185+

- Total prospects assembled to date using 3D seismic data from the many leads that exist in the data = 109

- Accuracy of our 3D seismic data in recent years = 80%

So Whats Next?

Ranken Energy acquired, on a proprietary basis, 324 square miles of modern, high effort 3D seismic data in a fairway extending north to south in south-central Oklahoma in which we initially identified over 100 structural prospects.

Modern 3D Seismic Coverage in Square Miles

Want to learn more about upcoming projects?

Then, contact us at 405-340-2363

Our 3D Seismic Operation

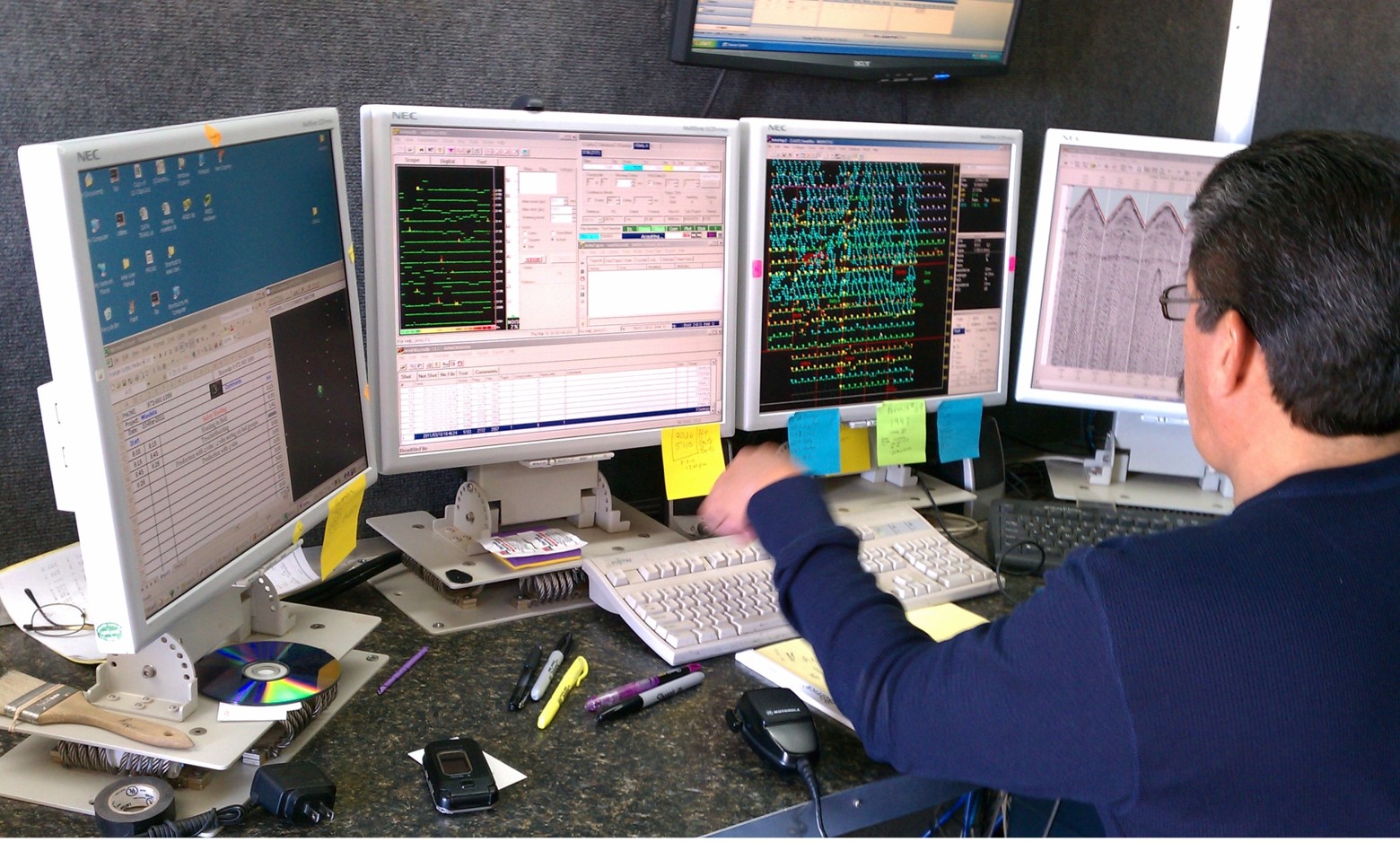

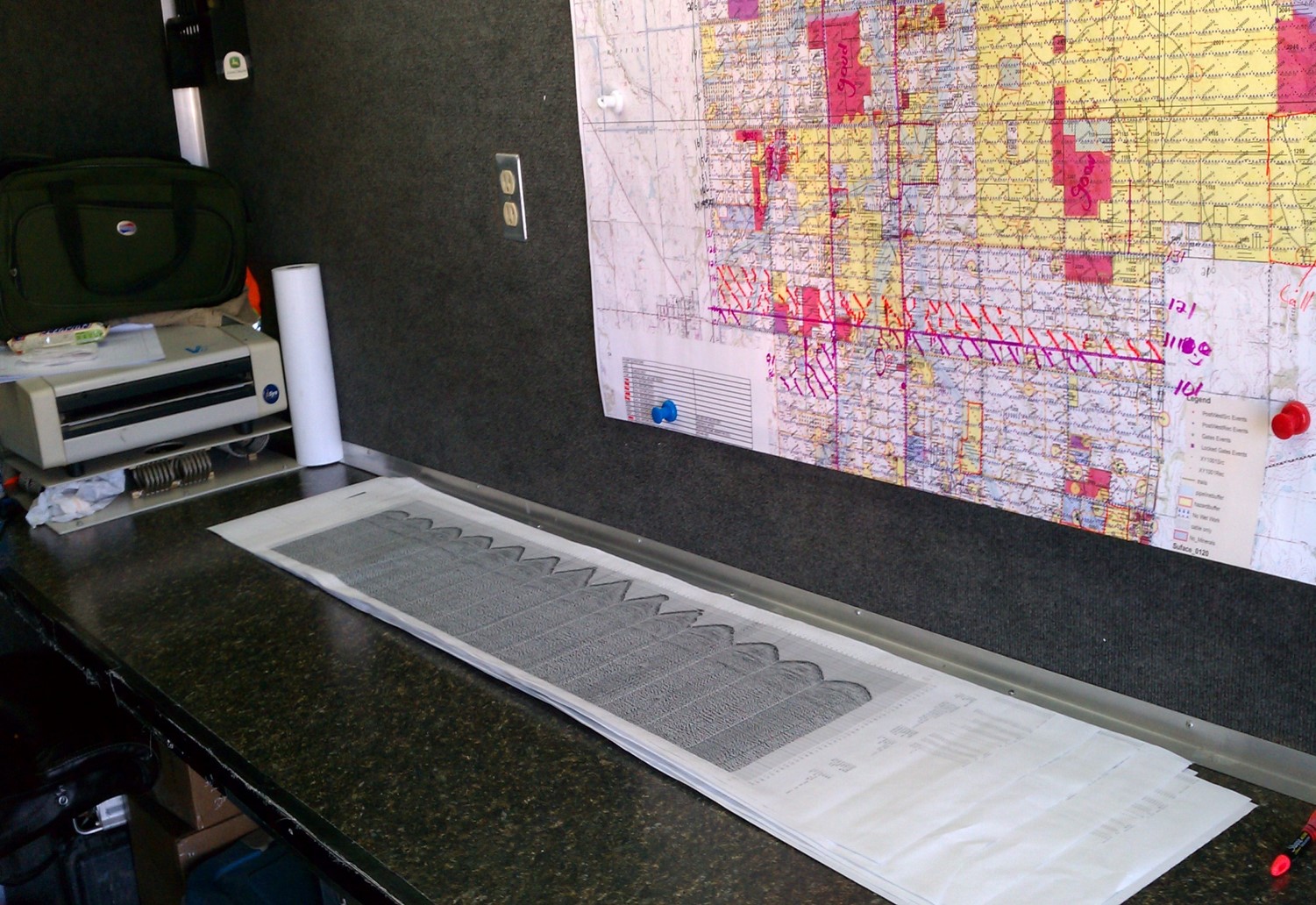

Here are some photos of our most recent 3D seismic operations.

To the left is a picture of the recording truck. All the data from all the geophones flows into this vehicle cab. The entire data collection operation is managed from here. The operations manager is in communication with every man on the crew via radio.

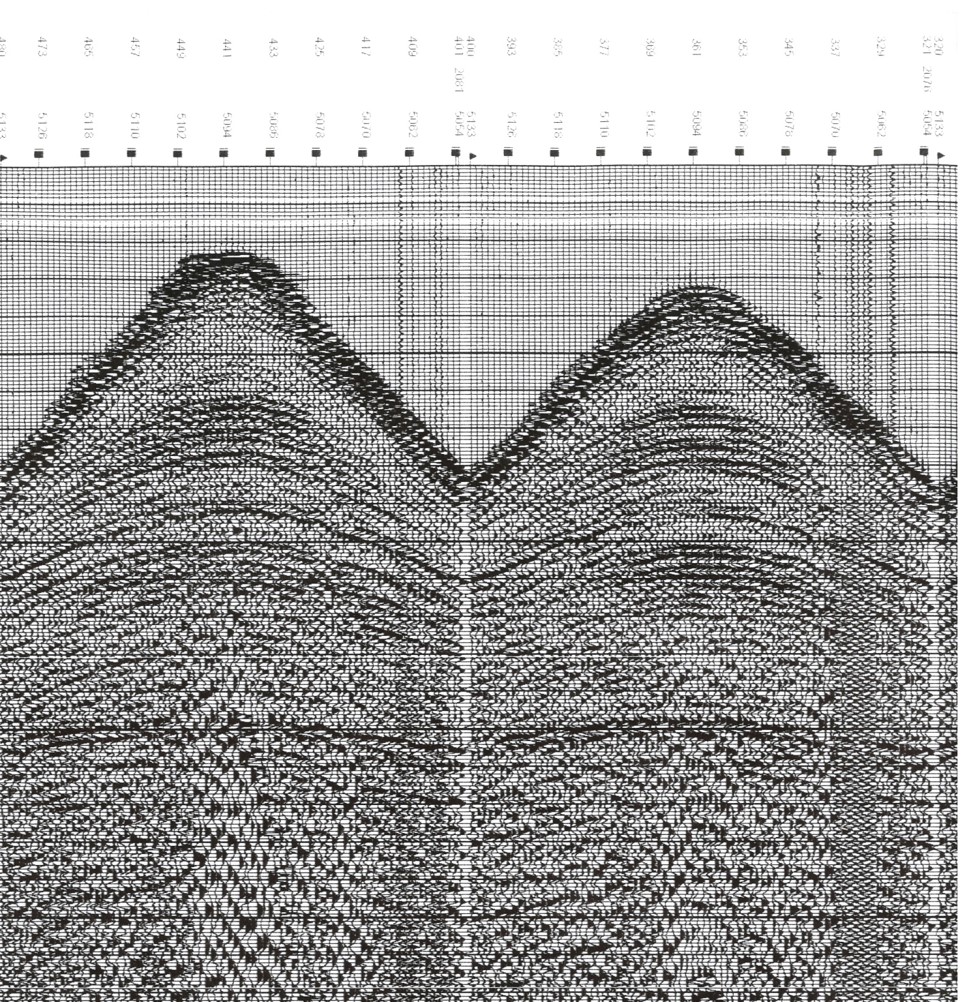

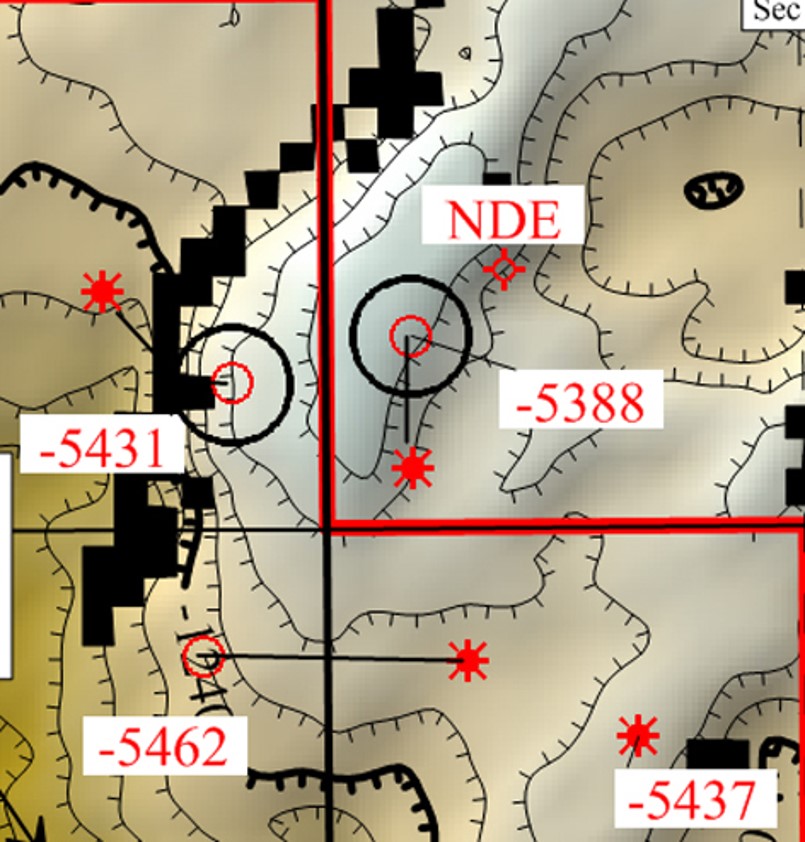

A seismic structural map generated out of the 3D seismic “cube.”

We produced over 1 million barrels of oil from this small feature.

Have questions or comments? We want to hear from you.

Want to learn more about 3D seismic?

Check out these additional resources and videos.

Video source:

Luke Patrick Illustrations

Video source:

MaurinMedia

Video source:

PolarPetroleum

Learn more about Ranken Energy